Lead Screw, The Future Of High Tech Machinery

Over the years, giant factories and machine based industries have used Lead screws instead of Ball screws. The market for Lead screws has shot up significantly over recent years. The main factors behind this immense growth are the cost-effectiveness of the product.

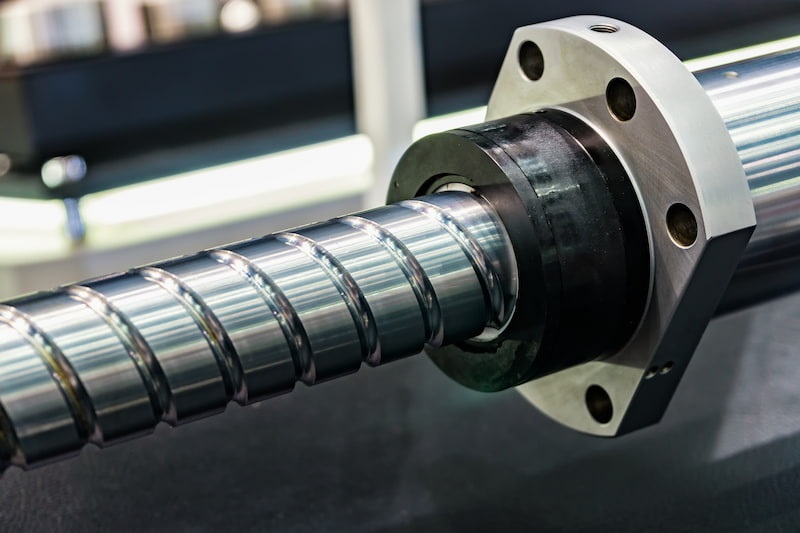

Nowadays, various models are widely available in the market; the Lead Screw Model DCM (ลีดสกรู รุ่น DCM which is a term in Thai). This is also a similar type of lead screw mostly used in big machinery to reduce cost and increase productivity. The design of the lead screw is divided into three main parts: the screw shaft, thread, and nut. All of these must be put together to put the screw into use.

What Do You Mean By Lead Screw?

The lead screw is a mechanical liner used to convert the rotational motion into a linear one. It also reduces friction when it comes in contact with a larger contact area. The parts of the screw are worth tighter to provide effortless motion. It provides increased wear resistance and provides additional mechanical support to the shaft.

Advantages Of Using Lead Screw

The advantages of using a Lead Screw are as follows.

- Lead screws are comparatively less expensive than ball screws that are widely available in the market hence, and it is a pocket-friendly alternative that also serves your purpose.

- It can be used in various appliances, machinery, and appliances that work at low to medium speeds. Their weight should also range from light to moderately heavy machinery to ensure smooth functioning.

- They are more compact as compared to other kinds of screws that are available in the market. It is mainly because lead screws have three parts, while the different types of screws have several parts that need to be assembled step by step.

- Lead Screws come with a self-lock facility, which makes them even more enjoyable. The self-locking facility ensures no external force is required to lock the screw.

- It is a highly strong, stable screw that prevents friction between the machinery parts. Hence they do not create any unnecessary sound while operating as well. It works silently.

- They come self-lubricated. Hence these screws do not require lubrication from time to time to ensure smooth functioning. They are usually coated with lubricating paint at the time of production.

Conclusion

The main purpose of writing this article is to help you understand the immense benefit you can avail yourself of with this product. I hope you will find this article helpful if you need more expertise regarding mechanical parts and their functioning.

Therefore, give this product a fair shot if you want to increase the productivity of your machinery at a lower cost. It will help you get maximum results at a lower effort. Moreover, you will control your cost by up to 50 % just by using this product.